Continual enhancement of the quality of existing products, as well as NPD, is key to the success of a brand. Using sophisticated texture analysis instruments, manufacturers can ensure high quality production and, ultimately, consumer satisfaction.

Weight management and healthy eating are still top of the agenda for today’s consumer. Recent reports show that consumer awareness of the importance of nutrition and nutritious consumption is ever increasing – statistics which are supported by an upsurge in sales of low-fat, low-calorie, high-fibre and omega-3 rich products.

Unfortunately, in responding to consumer demand for healthier products, manufacturers usually have to remove or add ingredients, which can have an adverse effect on the texture and palatability of the finished product. As a consequence, the consumer’s quest for healthier alternatives often leads to the sacrifice of optimum texture.

Numerous surveys have demonstrated that a product’s texture is closely linked to its popularity. Texture analysis provides manufacturers with an effective way of scientifically testing the textural properties of their products to evaluate consumer appeal. The toughness of a sausage, for example, could impact on the success of a brand.

Consumer loyalty, on the other hand, could be influenced by the softness of a loaf. With a wide range of application possibilities, texture analysis can be used across many sectors of the food industry – from meat to bakery and dairy – in order to achieve greater consumer satisfaction when it comes to textural issues in healthy foods.

Meaty issues

From the Lincolnshire to the Frankfurter, sausages are a traditional favourite in many cultures’ diets. However, in their efforts to pursue a healthier lifestyle, many consumers are reaching for low-fat varieties. The texture of a meaty sausage is an important factor in determining its palatability and, unfortunately, fat has always played a key role in creating desirable mouthfeel. Too little fat and the product could be tough, dry and bland.

Analysing the texture of low-fat sausages can provide an effective way to measure the effects of fat-reduction on the finished product. Using texture analysis, various tests can be carried out on chilled, frozen, pre-cooked or coated sausages to gauge the quality of their mouthfeel, and, in turn, determine consumer appeal.

An effective method of analysing the textural quality of sausages is the Warner-Bratzler Shear Test,

which measures the force required to slice through a sausage, thus

reflecting the level of ease with which it is consumed. For use in

conjunction with the TA.XTplus texture analyser, this fixture is one of the most widely used devices for analysing the textural properties of sausages.

An effective method of analysing the textural quality of sausages is the Warner-Bratzler Shear Test,

which measures the force required to slice through a sausage, thus

reflecting the level of ease with which it is consumed. For use in

conjunction with the TA.XTplus texture analyser, this fixture is one of the most widely used devices for analysing the textural properties of sausages. The Warner-Bratzler shear comprises of a V-shaped cutting blade, a triangular inset and a blade guide to ensure optimum control and precision. The arm of the TA.XTplus brings the blade down at a constant speed to cut through the sausage sample. The higher the force required to cut through the product, the more difficulty a consumer would experience in biting the meat.

Analysing these effects enables manufacturers of meat products to identify textural issues and adapt the formulation and composition of their healthier low-fat products as required, ensuring optimum texture and consumer satisfaction.

Dairy Important

As consumer demand for ‘better for you’ products has grown, low-fat dairy products, and in particular cheeses and yoghurts, have become a standard feature on supermarket shelves. However, the reduction of fat content within these products poses quality problems for manufacturers, often resulting in an unsatisfactory mouthfeel or disappointing texture. Effective pre-testing of cheese and yoghurt can help to identify textural problems and allow manufacturers to enhance the quality of their finished products.

With fierce competition in the market for healthy yoghurts, the dairy industry now also faces the problem of fat removal and how it affects product texture. When purchasing yoghurts, consumers pay great attention to nutritional value. However, when consuming the yoghurt, the evaluation of its quality is often heavily based on mouthfeel.

|

| Back Extrusion Rig |

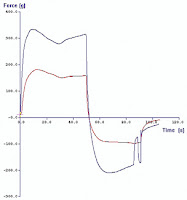

For conclusive results, the texture of both full-fat and low-fat yoghurts can be analysed and the results compared. Stable Micro Systems’ Back Extrusion Rig, for example, reveals the force required to extrude both types of yoghurt up and around the edge of the fixture, highlighting the difference in product composition. Typical results reveal that low-fat natural yoghurt requires considerably more force than the full-fat version, indicating a thicker, firmer texture.

|

| Comparison of consistencies of full- and low-fat yoghurt when subjected to back extrusion |

Bread with bounce

Also responding to pressure for healthier options is the bakery industry. In an attempt to move away from its traditional, unhealthy image, many manufacturers in the sector are incorporating functional ingredients into their products, such as added fibre.

One popular example is bread. As the health benefits of high-fibre diets are becoming increasingly recognised, more and more manufacturers are opting to fortify their products with fibre, which sometimes results in a harder, less appealing crumb.

|

| Comparison of freshness of two types of packaged loaves of bread |

Stable Micro Systems’ Bread V Squeeze Rig scientifically tests the softness of bread by imitating the process of manually squeezing a loaf of bread between the thumb and forefingers. Comprising of ‘V’ shaped rounded fingers, the rig is lowered onto a packaged or unpackaged loaf and the force required to compress the bread is measured. Typical results show that the lower the force and the higher the value of springiness, the fresher the loaf.

Using this test, manufacturers of fortified breads can evaluate the textural differences of their products and identify any problems that arise due to the addition of fortifying ingredients. With the information obtained, they can make the necessary adjustments to ensure their products meet today’s stringent consumer demands for healthier breads that do not compromise on freshness and textural appeal.

Tackling textural issues in healthy foods

As food processors continually strive to produce healthier products – be it low-in-fat or high-in-fibre – without impacting on their textural appeal, texture analysis is playing an increasingly significant role. Providing essential data on the impact of fat reduction and the incorporation of functional ingredients, it is proving to be an invaluable tool in many food sectors. Using the latest texture analysis instrumentation, manufacturers can tackle the textural issues associated with ‘better-for-you foods’, to ensure consumer satisfaction and ultimately secure brand success.

For more information on how to measure texture, please visit the Texture Analysis Properties section on our website.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.

The TA.XTplus texture analyser is part of a family of texture analysis instruments and equipment from Stable Micro Systems. An extensive portfolio of specialist attachments is

available to measure and analyse the textural properties of a huge range of

food products. Our technical experts

can also custom design instrument fixtures according to individual

specifications.No-one understands texture analysis like we do!

To discuss your specific test requirements, click here...

|

0 Comments